Description

Features

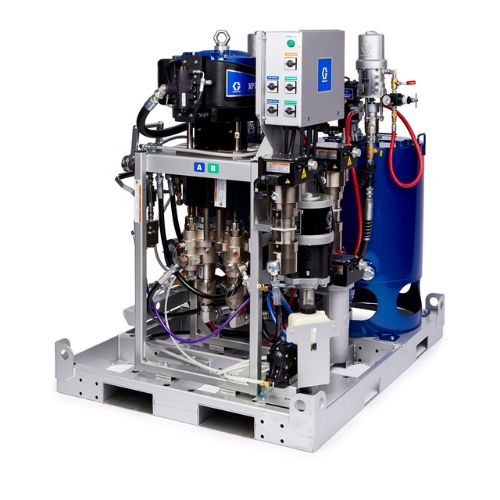

The XP70S-HF model is designed as an all-in-one, turnkey solution with heated conditioning tanks, ensuring faster material preparation. Engineered for high-volume fluid handling, this system enhances efficiency, increases flow capacity, and speeds up operations—making it the ideal choice for large-scale industrial applications that require both high flow and high pressure to support multi-gun setups or large-tip applications.

The Graco XPs-HF skid-based system seamlessly integrates the XP-HF sprayer with advanced material conditioning for superior performance. This system is built to reduce waste, accelerate cure times, and maintain precise mix ratios. The durable, heated, and agitated tanks ensure optimal material conditioning, meeting the demands of the toughest applications while boosting productivity. The XP70S-HF models are available with 1:1, 2:1, 3:1, or 4:1 mix ratios, allowing flexibility for various industrial needs.

Exclusive Xtreme Pump Lowers

- Proven reliability for consistent performance

- Available in multiple sizes for fixed mix ratio adjustments

- Effortlessly swap one or both lowers to achieve the desired mix ratio

- Heavy-duty piston rods ensure extended durability

XL10000 13-Inch Air Motor

- Built for continuous operation with anti-icing technology

- Constructed from heavy-duty aluminum, steel, and composite materials for long-lasting performance

- Equipped with a de-icing valve to prevent freezing in extreme conditions

Viscon HF Primary Heaters

- Enhances spray pattern by reducing coating viscosity

- Fully accessible heater core with serviceable heating elements

- Designed for easy maintenance and quick servicing

Mix Manifold

- Simplifies fluid control for both mixing and flushing operations

- Handles high-solids coatings with oversized porting, reducing pressure drop

- Can be mounted on the unit or positioned remotely for greater convenience

Ratio Assurance System

- Compatible with both Hazardous and Non-Hazardous models

- Continuously monitors A & B differential pressure to ensure accurate mix ratios

25-Gallon Stainless Steel-Lined Heated Hoppers

- Double-walled construction with 3,000W heaters for optimal material conditioning

- Xtreme-Duty agitators effectively mix high-viscosity coatings

- 5:1 Monark Feed Pumps efficiently transport material from the hopper to the pumps

Outlet Manifold & Valves

- Integrated fluid gauges to monitor pump output

- Automatic overpressure relief for added safety

- Allows circulation back to supply for easy priming, purging, or relieving pressure

- Enables fluid warm-up circulation with built-in heaters

Reviews

There are no reviews yet.